Silkron® Equiptor

Silkron® Equiptor is an Equipment Management System designed for the production floor to keep track and monitor the equipment productivity, performance, availability, utilization and downtime as well as Overall Equipment Effectiveness (OEE) analysis. It also facilitates the task of tracking the due dates of equipment preventive maintenance and calibration.

Silkron® Equiptor allows the manufacturer to track the utilization of all equipments in the production and the efficiency of the plant operations. From the system, the production operations can be optimized to reach the maximum capacity by identifying and monitoring the major roadblocks and root causes to that production goal. Silkron® Equiptor is designed to enhance the productivity through the analysis of equipment uptime and downtime.

Silkron® Equiptor allows the manufacturer to track the utilization of all equipments in the production and the efficiency of the plant operations. From the system, the production operations can be optimized to reach the maximum capacity by identifying and monitoring the major roadblocks and root causes to that production goal. Silkron® Equiptor is designed to enhance the productivity through the analysis of equipment uptime and downtime.

Generally, the operations of most manufacturing plants are running at only 60% efficiency during uptime. The other 40% of the total equipment time are lost due to various downtime. Among which, 15% of plant utilization are lost to scheduled downtime. Scheduled downtime can be preventive maintenance, setup, change of consumables/materials, production test and so on. Unscheduled downtime accounts for 10%, which is usually difficult to quantify but preventable if proper preventive measures are taken. The remaining significant 15% of the total utilization is lost as hidden downtime. Hidden downtime can be due to shift interruptions, minor maintenance issues, operator not available and so on, which are difficult to quantify and remain unnoticed without a monitoring system.

Plant Utilization Statistics

Modules in Silkron® Equiptor

Moreover, Silkron® Equiptor is also designed to track the maintenance activities for the production equipment, such as Preventive Maintenance and Calibration. These maintenance activities can be scheduled into the system and friendly prompt reminder will be sent to ensure that proper maintenance are conducted to the production equipments.

With its incorporated Inventory module, spare parts, conversion kits, test boards and any other parts for the production can be managed easily and effectively. Integrated with the Maintenance modules, analytical reports can be generated to comprehend in details on the equipment expenses for consumables and maintainability.

With its incorporated Inventory module, spare parts, conversion kits, test boards and any other parts for the production can be managed easily and effectively. Integrated with the Maintenance modules, analytical reports can be generated to comprehend in details on the equipment expenses for consumables and maintainability.

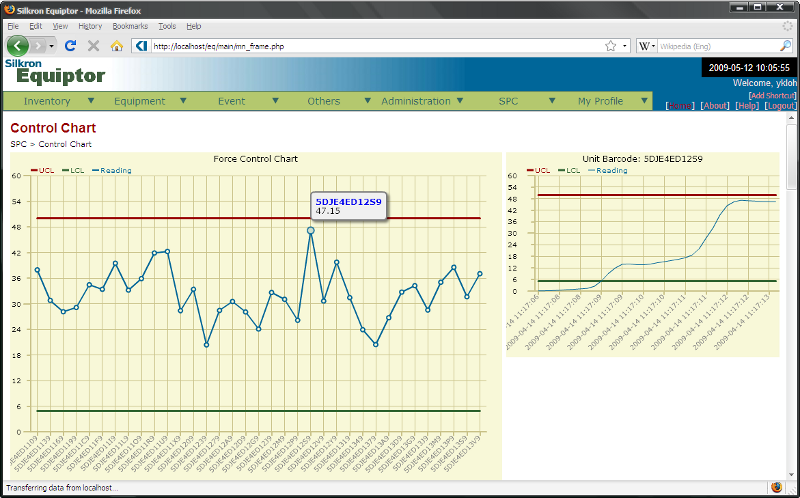

Equiptor Screenshot